How Track-n-Trace of Your Products Can Help in Improving Vendor Claims?

You must have heard a lot on track-n-trace off late, thanks to the Government’s initiative in the Pharma sector to protect India’s brand image for safe and quality drugs amid growing concerns on counterfeit and fake drugs in the market. Let us get to the root of this term in a layman’s language.

Track is to understand present and historical locations of a serialized item. Trace is to understand the history of who all came into contact with the item along its journey in the supply chain. In the pharmaceutical supply chain context, track and trace refers to the process of determining a drug’s current and past locations. When track and trace is implemented accurately, a drug can be tracked throughout the supply chain and traced back up the supply chain upon return or recall.

We now extend this concept to other non-pharma sectors. In the distribution of commonly used products, track and trace is the process of determining the current and past locations (and other information) of a unique item or property. When we put our investigative lens, we identified that one area where brands face an issue is in managing vendor claims during product returns. Vendors are typically the second largest expense behind labour and hence important to the P&L.

Manufacturing of every Finished Good involves various parts supplied by multiple Raw material vendors. Many a times, a single part is supplied by more than one vendor. In such scenarios, whenever a product return takes place, it becomes very difficult for the manufacturer to pin point the vendor even when the reason for the product defect is identified. Vendor relations go for a toss when the blame-game begins to fix accountability for defective parts. It may also result in vendors choosing not to supply materials to the manufacturer. This leads to the FG manufacturer absorbing losses due to product returns.

Since there is no transparency in knowing what materials supplied by which vendor has gone into making which particular product(s), it leads to lack of accountability. Digital supply chain software is changing how vendor management is done by providing supply chain traceability.

Supply chain traceability and transparency helps companies to know the upstream happenings in the supply chain and to communicate this knowledge both internally and externally. There are Radio Frequency Identification i.e. RFID solutions and QR code based solutions that help to establish this communication. One such solution that is available in the market is from Sepio.

Sepio’s Logitrak solution helps a company to do the following:

- Digitize Raw Materials at the Batch Level by Creating a Unique Identity for Each Batch of Raw Materials

- Link Each Serialized Raw Material to a Serialized Finished Product at the Time of Manufacturing

- Track and Trace Each Fg as Well as Its Shipper and Pallet Through Its Journey from Farm to Fork

- Capture Key Data Points During a Product’s Journey in the Supply Chain That Can Help in Achieving Supply Chain Traceability

The process of digitizing can be done through multiple ways like RFID solutions, NFC and QR codes. Usually, companies with large volumes of SKUs go for Smart Packaging solutions by printing a QR code on each SKU since it is cost effective compared to NFC and RFID solutions. By enabling track and trace, a company can now know which Raw Material went into which FGs at an SKU level. This helps to identify the supplier during a product return or recall, thus increasing the accountability.

As a result, the manufacturer can benefit in multiple ways through smart packaging. This will help to reduce losses by fixing accountability on the vendor who supplied the faulty material in making that particular FG. The other benefit being that the vendor relations won’t be affected due to the earlier blame game. It will rather improve the quality of the materials being supplied, thereby resulting in increased product quality and an enhanced customer experience for your clients. Thus, supply chain traceability has multi-fold benefits.

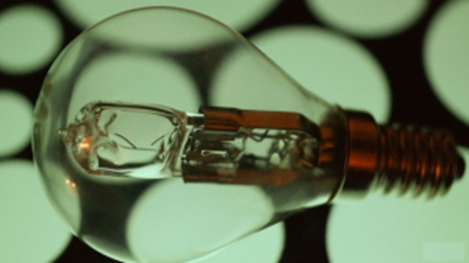

In the case of one leading Consumer Goods brand, they were facing this issue of losses borne due to increased product returns of LED light bulbs.

There were various parts supplied by different vendors being used in the making of one bulb. During a return, the inability to pinpoint a faulty vendor led to losses for the brand when the FG was returned by the customers. Now, smart packaging by mapping the Raw Material to the FG, they were able to address this issue, thereby resulting in increased profit for the brand along with the added advantage of improved product quality.

Do share your thoughts on this topic and share this article in your professional circle. Feel free to contact Sepio at [email protected] if you are interested in seeing a solution demo on how we can optimize your supply chain operations.