Top Trends to Watch Out for in Supply Chain Management in 2021

2020 has been a turbulent year with major changes across industries and traditional business models.

The arrival of 2021 will be all about having contingency plans with sustainable operations that can easily adapt to sudden market tremors and save companies money on restructuring the supply chain.

Let us have a look at the key trends we can expect in supply chain in the upcoming year.

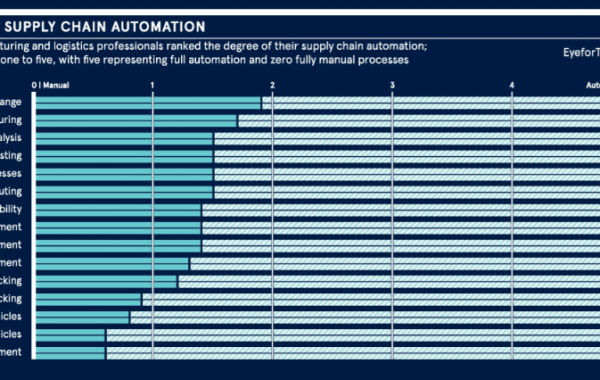

Automation

Supply chain is always on a lookout for new technology to give a competitive edge in terms of speed and efficiency. Advancements in robotics, machine learning, RFID solutions and automated trucking has enabled supply chains to optimize its performance. Automation easily solves the pain areas of shipping demands, customer service, managing labor, real time inventory management and labor.

Industry leaders like Amazon have already implemented automated supply chain solutions and set the bar for the rest of the industry to follow in their retail operations. Supply chain automation can take the entire transportation process and streamline it with the hope of cutting down on delivery costs. Without the need for a sophisticated team to figure out trucking details, companies can focus on pressing issues while automation brings in the best solutions and reporting to your consumers and stakeholders.

Internet of Things (IoT)

After understanding the importance of automation, it becomes important to understand the way in which one can achieve the same. IoT devices have revolutionized supply chain management (SCM). It’s much easier to understand where goods are, how they are being stored and when they can be expected at a specific location. Adding IoT capabilities to the supply chain would not only digitize the supply chain from farm to fork but also enable superior Inventory management, Fleet management, shipment monitoring. IoT would also enable real time inventory movement and capture important data to be used for demand and supply planning.

A simple IoT software integration with existing ERP systems would make traceability, authentication and consumer engagement implementable. Companies like Sepio products enable a digital and automated supply chain using IoT solutions, RFID and smart labels and sensors.

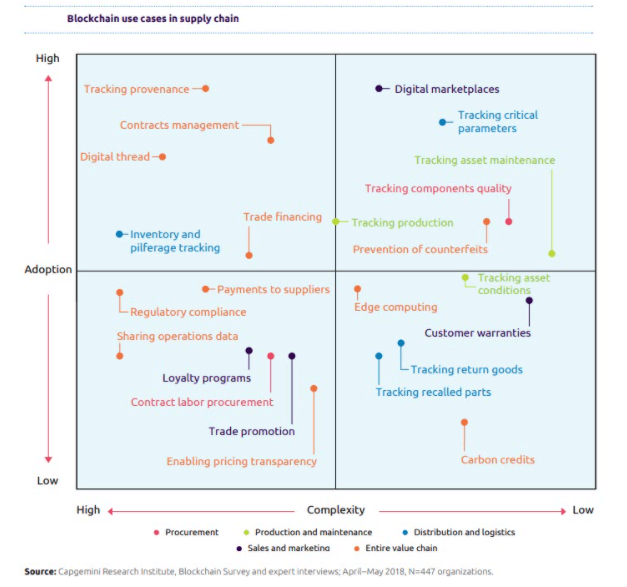

Block chain

As supply chains grow more complex in nature, involve diverse stakeholders, and mainly rely on a number of external intermediaries, blockchain has emerged as a strong contender for de-tangling all activities to be regulated separately however still linked to display the overall status.

The food supply chain will likely be the first one to undergo major blockchain transformation, especially when it comes to the distribution of fresh produce. Recalls have been a major and costly industry issue for years. Thus, several major food-borne bacteria outbreaks, which have recently happened in the US, are encouraging more and more companies to look into blockchain as a new method for increasing visibility and traceability of the goods.

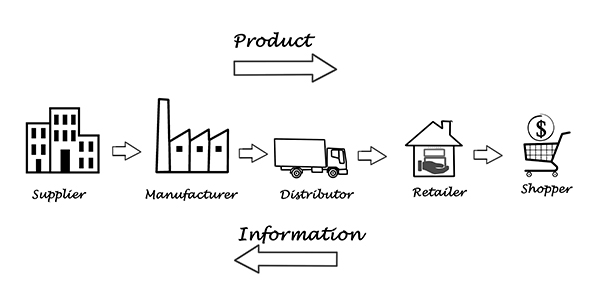

Supply Chain Traceability and Visibility

Supply chain traceability is all about knowing where the inventory is at a particular time, and how well components, parts, or products in transit can be traced as they move from the manufacturer to their final destination. Improving and strengthening the supply chain is the ultimate goal of supply chain visibility. This would not only help with managing the complex supply chain but also help with changing compliance, product recalls and meeting product demands.

To achieve supply chain traceability, products are serialized and aggregated during the manufacturing process. An electronic cargo tracking system or RFID Eseal secures and tracks the journey during transit and a track and trace system enabled by intelligent packaging or smart packaging gives additional data till the point of sale. Smart packaging can also provide data from the retail shelf – who scans the product, how often, where and when. All this data can then be used by a company to improve their supply chain management, digital marketing and sales spend.

Elastic Logistics

The name Elastic logistics has been making the rounds over the last few years in the supply chain world and is touted as an exciting development. Elastic logistics is being driven both by big data and also by increased automation. Automation is an agile, flexible way to increase and decrease an organization’s logistics infrastructure in both an expedient and cost-effective way. Automated solutions and machines, when available, can be deployed as necessary, and an organization can only implement the resources that it needs. In this way, elastic logistics is the natural evolution of the supply chain with the application of new technologies of data and machine automation that have been emerging.

An Electronic cargo tracking system has an inbuilt ability to gather information related to the product journey and allows fleet management, optimize routes and minimize risks. RFID solutions such as RFID eseals can transmit similar data during transit. Their usage will drive data driven logistics leading to increased efficiency and service quality.

To summarize, we have entered the age of digital innovations with ready to implement technologies for track and trace, serialization and automation.

To catch up with digital supply chain management trends of 2021 and improve your businesses bottom line, connect with Sepio Products on [email protected]