Smart Packaging Led Strategy to Achieve Your 2021 Business Plan

Global counterfeiting accounts for almost around 8 to 10% of global trade, or about $600 billion annually as per Organisation for Economic Co-operation and Development. According to Philip Swinden, head of Publications and Events for Pira Intl., a U.K.-based research organisation, sophisticated and innovative new packaging and supply chain technologies which helps in better Smart Packaging Solution are increasingly being introduced to resist intellectual property and goods counterfeiting.

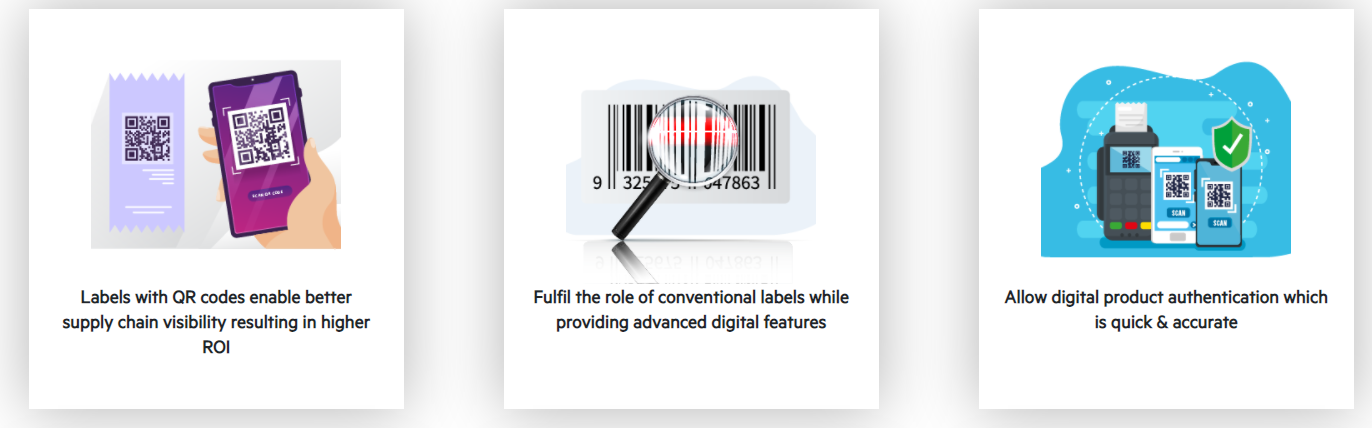

As a result, effective solutions rely on collaboration–between technology providers, brand owners and law enforcement, market segment leaders, consumer goods companies and their customers to improve customer engagement, and departments within a manufacturing organisation. QR code on packaging or smart packaging is critical for managing the supply chain through the digital medium.

The smart packaging market is expected to reach USD 2.89 billion by 2021-2025, according to Technavio. Market segmentation by end-users (food and beverage, healthcare, personal care, automotive, and others) and geography is fully covered in the market report (North America, Europe, APAC, South America, and Middle East and Africa). According to the report, North America will account for 44% of market growth over the forecast period.

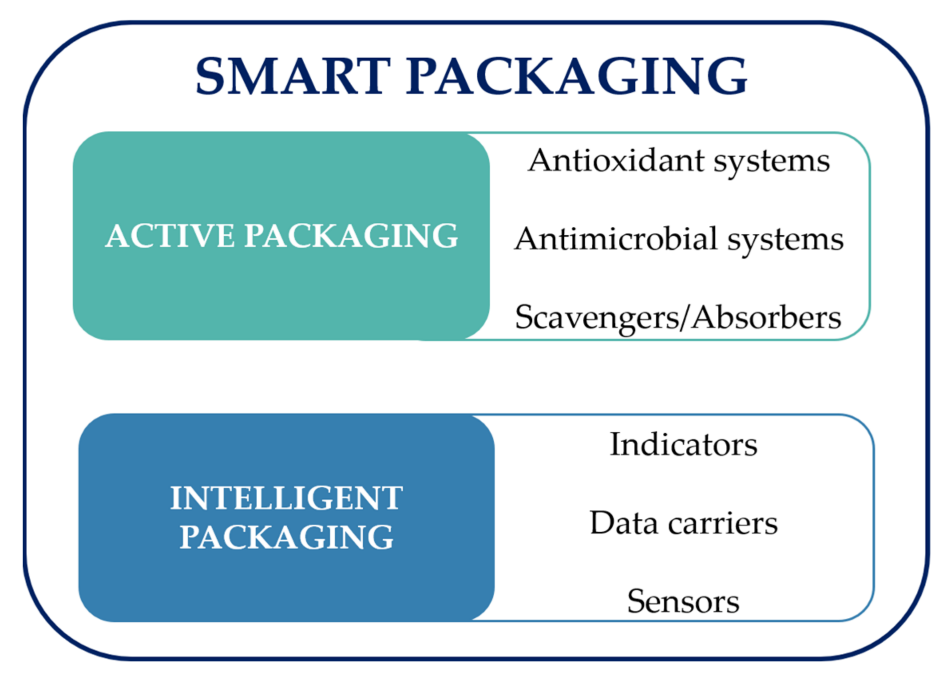

Digital Packaging plays a vital role especially in the food industry. Active packaging helps to reduce food waste by extending the shelf life of products and providing accurate information to consumers through smartphones. It is one of the best ways to prevent food from damage and spoilage throughout the supply chain. Food packaging experts use digital packaging methods by adding sensors in packaging to monitor the acidity level of the food which could be read with the scanner to assess the freshness of the food content. However, the main challenge of using this Digital supply chain is that it involves high cost.

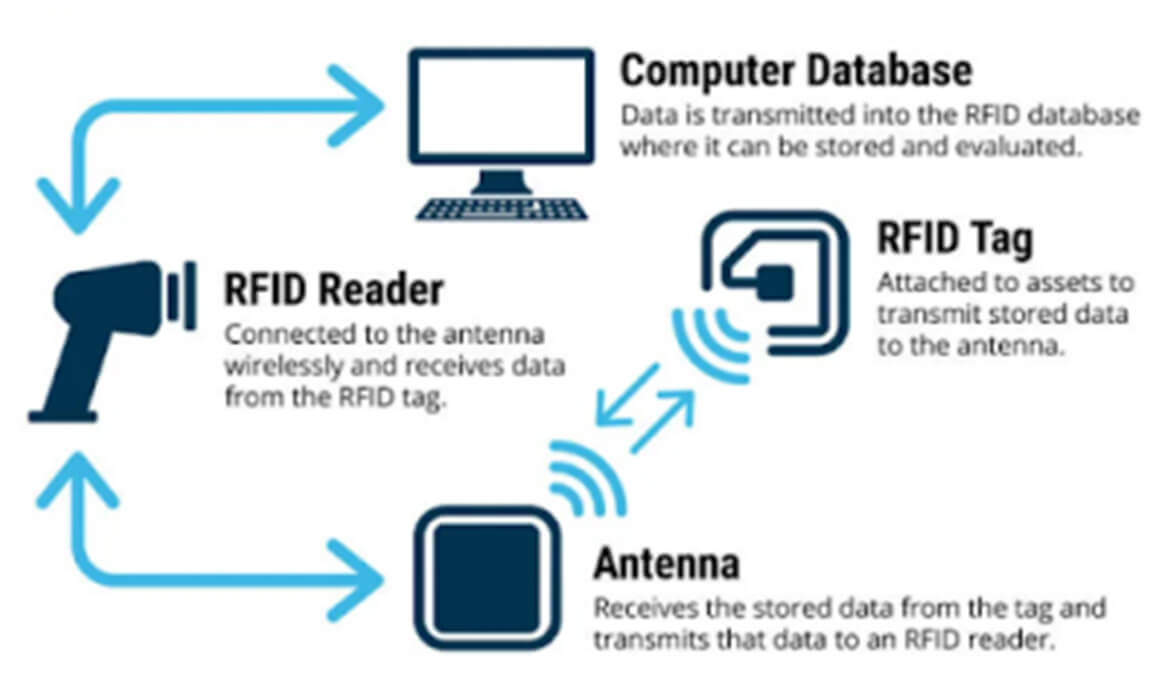

To overcome this challenge people started using intelligent packaging, which is a component of smart packaging, to overcome this challenge. In ‘intelligent’ packaging, the package function responds to changing external/internal conditions by turning on and off, as well as increasing Track and Trace System by communicating the product’s status to the customer or end user. “Packaging that senses, informs, and involves smart logistics” this is how intelligent packaging is defined.

Knowing whether a package has been tampered with is equally important to consumers as it is for the brand. Tamper-evident technologies that are difficult to duplicate, such as those which are based on optically variable films or gas sensing dyes that cause irreversible colour changes, will become more common and cost-effective for disposable commodity packaging. Piezoelectric polymeric materials could be used in package construction to change the colour of the package when it reaches a certain stress threshold. A ‘self-bruising’ closure on a bottle or jar could indicate that attempts to open it have been made.

Everyone is dealing with unprecedented times right now. Because business is impacted and there is a high demand for certain goods and services, smart logistics with a digital supply chain is required to reduce human labour and ensure that the supply chain is not impacted. According to a recent survey, 19% of users in the United States and the United Kingdom strongly agreed that there has been a visible increase in QR Code usage in the supply chain since the start of COVID-19. By 2022, 17 million people in Southeast Asia and 9 million in India will have scanned Product QR codes for the first time.

According to the recently released Foresight report ‘Materials: Shaping Our Society,’ the package of the future will increasingly operate as a smart system including both smart and conventional materials, adding value and benefits throughout the packaging supply chain. Smart materials must be inexpensive in comparison to the value of the product, dependable, accurate, and repeatable in their range of operation, as well as environmentally friendly and food contact safe.

Brands have been able to grow their bottom line by enabling a digital supply chain using Smart packaging solutions. Smart packaging has also improved their brand image in the market. Dr Ashim Biswas, Chairman of Biswas group recently said that their revenue increased ~250% by implementing a digital supply chain. Similarly Mr Mukul Negi, Head Supply chain & logistics from the Agro industry says that there was a drop of 90% in incidents related to product duplication, which helped in brand protection. Similarly, several executives from the FMCG industry state that their revenue increased by over 70% by using smart packaging solutions and it is going to play a major role in the future growth of the industry.

Sepio Solutions offers a seamless platform to digitize your supply chain to improve supply chain traceability, product authentication and personalized consumer engagement using Smart Packaging. Contact Sepio for all your smart packaging needs by emailing at hello@sepiop

Add Comment