Smart IDs Enabled by Serialization: Key Benefits to Your ERP

Enterprise Resource Planning (ERP) is a software solution which streamlines and integrates the various operations and processes, and directs the flow of information into a unified system. A typical ERP system consists of computer software and hardware to achieve the integration. For manufacturing companies, an ERP system provides a standalone solution which means, you can get information about your business at any time. It has better managerial capability to manage product data from different aspects.

Traditionally, products have been tracked through batch numbers which are given to multiple units of a product created during the same time. The current ERP system used in companies are equipped to record data for these batch of products created under one section instead of having the ability to identify each individual product. This is not very useful once the batch is broken down for distribution. Some of the key challenges with batch level ERP tracking include:

- Open to Pilferage and Anti Counterfeiting Solution

- Unit level QC Issues Cannot Be Easily Traced Back

- Lack of Recall Integrity

- Product Diversion

- Visibility is Restricted Beyond Manufacturing Plant

Serialization is the answer to these issues. The introduction of Internet of things (IoT) and digital supply chain technology now allows brands to achieve 360˚ supply chain traceability solution for their goods. Serialization can be easily integrated with the existing ERP systems to make the data richer and improve business decision making. From the source of raw materials to the factory, the packaging, to the store shelf, and every stop in-between, the product journey can be an open book, providing companies with greater control over their inventory and consumers with the satisfaction of knowing that their item is exactly what they paid for and where it came from.

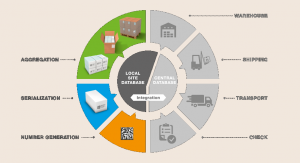

In the manufacturing process, each product is assigned a unique id which is then embedded into the product via an RFID solution or NFC chip or a Smart label. This is linked to a cloud software which then builds a parent child relation between the unique product code and batch number. A similar process links the batch number to the carton and subsequently to the lot/pallet number and updates the software about the movement of the product within the supply chain in real time.

As a result of integrating serialization with existing ERP system, the benefits to a company can be multi-fold:

- Know Where Every Unit Of Your Products Are At All Times

- More Accurate Demand Forecasting

- Supply Chain Visibility From Farm To Fork

- Track And Trace Raw Materials And Link To Finished Goods

- Access Detailed Information On Origin And Manufacturing Processes

- Guarantee Of Provenance And Authenticity With Anti- Counterfeiting Solution.

- Streamlines Processes And Reduces Operations Cost

- Improves sustainability by reducing paper and packaging consumption

Serialization enables to the company to pinpoint which units of products were loaded in which vehicle to be transported. An electronic cargo tracking system or an RFID eseal can secure the vehicle in transit to eliminate the opportunity for pilferage. This Electronic cargo tracking system is also an IoT product which can communicate with cloud about the whereabouts of the products making sure it reaches the right destination without diversion.

In an article by Bill McBeath titled ‘How the Pharmaceutical Industry Has Dramatically Reduced Thefts’ he credits a 50X reduction in pharmaceutical theft in the U.S. within 4 years due to traceability implementation. This was enabled by serialization and using software solutions to track and trace the journey of each product throughout the supply chain.

The ERP system can be integrated with the Software solution which enables serialization and also automates the process to update the product journey, push information for in-depth analysis, quick recalls with details on backwards and forward supply chain and regulates the shelf life of products. It has been successfully tried and tested in the Pharma industry and is now growing in the FMCG industry due to its numerous benefits.

Serialization goes beyond traditional batch level supply chain traceability solution to categorize and separate items at the time of production and distributed through the retail network or sold to end consumer. As such, serialization provides unit level traceability and potentially the ability to authenticate with anti- counterfeiting solution whether an individual item is genuine or whether that item has been distributed through legitimate channels. To date, the use of serialization as an anti-counterfeit solution is not widespread, but the potential is there.

Sepio offers market leading Saas products to digitize and secure your supply chain. You can connect with them on [email protected] for a demo of their supply chain traceability solution.