5 reasons why digital traceability needs to be implemented now!

Digital traceability as a technology allows producers to track and trace every item in the supply chain that is involved in making a finished product, from the suppliers to the final sale or as they say ‘farm to fork’ or ‘factory to consumer’. A digital supply chain is becoming more imperative for brands to invest in. Track and trace solutions not only provide critical information to consumers but also ensure product safety by fully controlling the supply chain. Smart packaging solutions have made the implementation of traceability simple and cost effective.

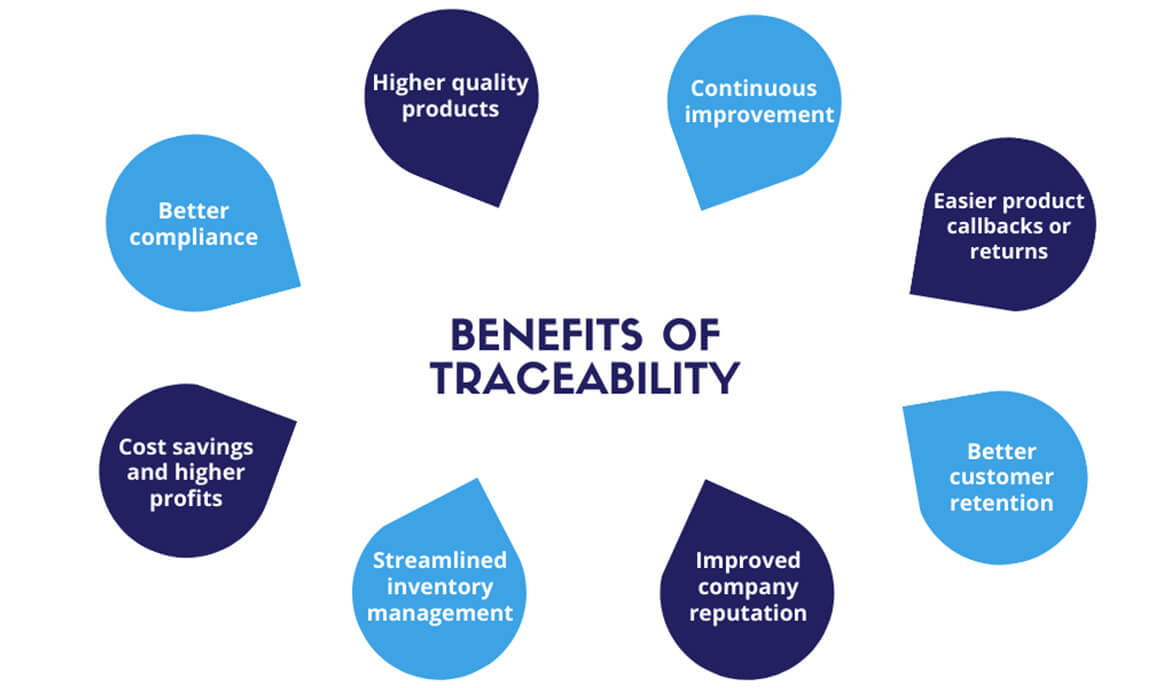

Let’s better understand what digital traceability can help your business with

Cost Reduction

Today, several companies depend on manual supply chain operations and processes. As a result, there are a lot of hidden costs in the supply chain. Digitization is the way forward for all industries – as a result, processes can be automated and optimized based on the data collected – this in turn helps reduce operations cost.

Track and trace solutions have had a positive impact on costs related to inventory management, sales returns, production waste and increased productivity due to better operations decisions that can be made.

Product traceability, enabled by track and trace solutions, allows companies to easily capture and analyze data on product diversion/infiltration. Similarly, product authentication which was not possible in a non-digital supply chain is now possible. As a result, companies can recapture lost sales and reduce operations cost at the same time.

Operational Efficiency

Track and trace solutions empower supply chain managers with real time data which is used for analyzing

- Process mistakes and rework

- Defective products reaching customers

- Late deliveries

- Inventory shortages

- Product recalls

Now, all plant and warehouse operations activities can be modified to drive better results by optimizing their processes to enable efficiency and reduce resource wastage. Product traceability helps ensure the risk of loss is kept to a minimum and provides key bits of information so that brand owners can take decisions when problems arise, sitting miles away.

Quality Control

Supply chain traceability provides much better control over the entire manufacturing process. Traceability encourages granular quality control right from raw material to work in progress to the finished product. It ensures transparency and accountability throughout the supply chain. Each product with a Smart Digital ID provides a documented trail of its product information, its journey, components, quality, and safety. It proves that products meet certain standards or comply with industry regulations.

The system is also capable of identifying hotspots with problems or distributor areas with infiltration issues, product authentication or counterfeiting problems or retailers with more than average returns so that a company can now take better action.

Decision Making Using New Data

Capturing data has proven to be amongst the most important benefit of a digital traceability solution. This answers questions for “what”, “when”, “why” and “who” along with details on quantity and unit level details. Track and trace solutions secures the upstream and downstream traceability for stakeholders and decision makers and the data acquired can be used to fulfill not only government compliances, which is done in case of Pharmaceuticals, but also for building brand trust and reliability by allowing the consumers to see a product’s journey.

This data can also be used to identify root causes of problems, optimize business opportunities, better planning and forecasting and make the supply chain flexible and responsive in case of any disequilibrium.

Competitive Edge

If you are implementing product traceability before your competition, then you would have an edge over the competition as there is more trust in businesses that are transparent about their operations in terms of their sourcing and suppliers. If your competition is already implementing traceability, then it’s definitely required for you to quicken the pace in the implementation to gain back any lost advantage..

As per Bain, “Traceability is the Next supply chain revolution, across most industries and sectors, we are already beginning to see companies with traceable supply chains start to outrun competitors with limited visibility”.

The ability to collect, validate, distribute and track supply chain data in a structured manner could lead to protection and optimization of existing revenue streams and the ability to capitalize on new revenue in B2B or B2C business relationships. So, the companies that take advantage of traceability will be able to use data and better support core business functions. The time to implement smart packaging solutions for brands is now. To get started with implementing a smart packaging solution for your brand, you can reach out to Sepio Solutions on [email protected]

Add Comment